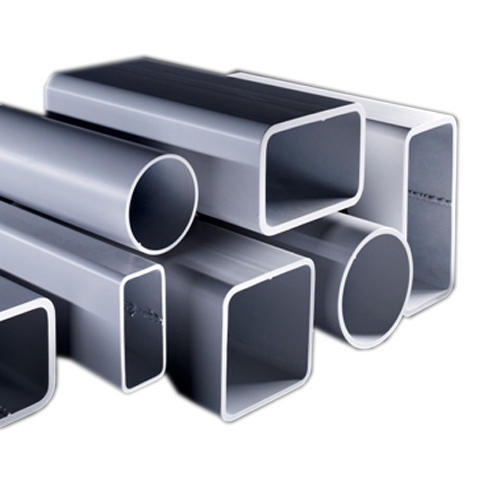

Product Description

We have been betrothed in supplying a finest range of MS Hollow Section Pipe. The provided pipe is manufactured by adept professionals using quality assured mild steel with the aid of modern techniques. This pipe is widely demanded in construction and engineering industries. Moreover, clients can purchase the offered MS Hollow Section Pipe from us at marginal rates.

Key Points:

- Excellent strength

- Longer life

- Sturdiness

- Corrosion resistance

Advanced Manufacturing ProcessProduced using ERW (Electric Resistance Welded) technology, MS Hollow Section Pipes ensure uniform strength and seamless joints. The process supports a range of sizes and thicknesses, meeting strict dimensional and straightness tolerances as per IS 4923 standards. This guarantees reliability and precision for structural applications.

Highly Customizable SolutionsThese pipes offer customization in terms of length, dimensions, end finishes, and surface protection. Clients can select from standard 6-meter lengths or request tailored sizes. Optional coatings, such as hot dip galvanization, black bitumen, or primer painting, enhance longevity and corrosion resistance to suit specific project requirements.

Versatile ApplicationsMS Hollow Section Pipes are suitable for structural construction, engineering, fabrication, fencing, furniture, and infrastructure development. Their robust yet adaptable design makes them ideal for support columns, frameworks, and versatile use across various sectors including industrial and commercial environments.

FAQ's of MS Hollow Section Pipe:

Q: How is the MS Hollow Section Pipe manufactured?

A: The pipe is produced using the Electric Resistance Welded (ERW) process, ensuring a strong, seamless product with consistent thickness and superior joint integrity. Quality checks are performed as per IS 4923 standards to maintain precise straightness tolerance and optimal physical properties.

Q: What end finishes and surface protections are available for these pipes?

A: MS Hollow Section Pipes can be supplied with plain or beveled end finishes. For surface protection, options include hot dip galvanization on request, as well as standard black paint, bitumen coating, or primer application to improve durability and resistance against corrosion.

Q: When should one choose optional galvanization for these pipes?

A: Hot dip galvanization is recommended if the pipes will be installed in environments with high exposure to moisture or chemical elements, such as outdoor structural frameworks, fencing, or industrial zones, as it significantly enhances corrosion resistance.

Q: Where are MS Hollow Section Pipes commonly used?

A: These pipes find extensive use in structural construction, engineering projects, fabrication, fencing, furniture manufacturing, and infrastructure developments. Their adaptability makes them suitable for both indoor and outdoor applications, ensuring stable support and aesthetic appeal.

Q: What are the benefits of choosing MS Hollow Section Pipes for construction and fabrication?

A: Benefits include excellent weldability, good cold bending properties, customizable sizes, moderate corrosion resistance (with optional coatings), recyclable material, and compliance with international standards such as IS 4923 and ASTM A500. Their structural strength, combined with lightweight design, offers efficiency and cost-effectiveness.

Q: Are the dimensions and lengths of MS Hollow Section Pipes customizable?

A: Yes, while the standard length is 6 meters and standard sizes range from 25x25 mm to 150x150 mm, both the length and dimensions can be customized to meet specific project or client requirements.